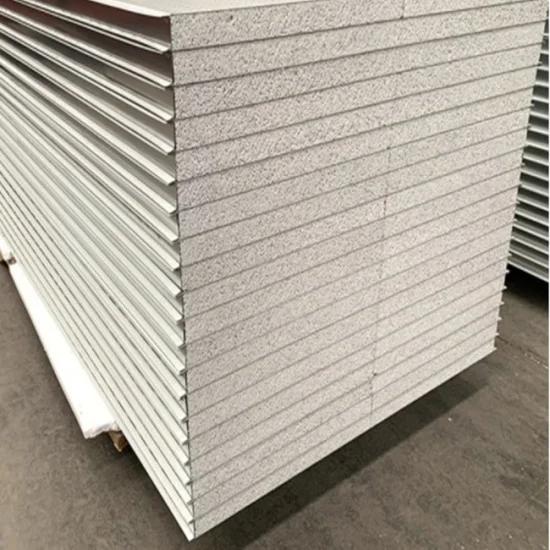

EPS Panels

EPS INSULATED PANELS – A BREAKTHROUGH IN INSULATION

Frost Prefab Engineering offers a comprehensive range of EPS Insulated Panels, widely applied in the building and construction industry. These panels are ideal for structures such as food processing centers, industrial roofing structures, wall cladding, partitions, walk-on ceilings, prefabricated shelters, accommodation shelters, information kiosks, health centers, community shelters, communication sheds, and high-altitude vacation shelters for sub-zero temperature locations.

Due to its optimal weight-to-strength ratio, EPS sandwich panels are the material of choice for several architectural components, including the construction of high-altitude camping shelters. Our EPS panels are examined according to established norms, and we adhere to industry standards. Additionally, each panel is tested for quality before delivery.

These panels can serve a variety of purposes due to their excellent strength-to-weight ratio and effective insulating characteristics. Our panels are in high demand because of their versatility and the wide range of applications they have. This EPS Panel is light and strong enough to be used in a variety of applications, including roofing, wall cladding, ceilings, and more. It’s also used to build high-altitude shelters for those living in extremely cold climates.

In addition, our professionals inspect the entire batch of products against rigid quality standards before sending them out the door. Customers can also be assured knowing that we offer this product at a very reasonable price.

EPS PANEL FEATURES

- Modular in nature and pre-engineered for precision and time-saving construction

- Multiple finishing options like PPGS and PPGL among others

- Available in a variety of dimensions

- Constant thermal resistance

- Light weight EPS Sandwich Panels which are easy to lift and install at any altitude

- Frameless construction entails flexibility of design, supply and installation for all structure types

- Measurable energy savings with minimal loss and highly efficient performance

- Tough and long lasting to suit any construction

- Long life and low maintenance

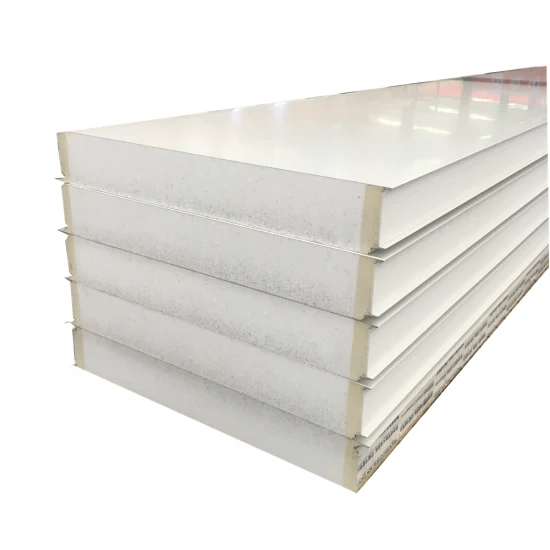

EPS SANDWICH PANEL MANUFACTURING TECHNOLOGY

The production process at Frost Prefab Engineering, the leading polyurethane foam (PUF) panels manufacturer in India, is a blend of innovative automation and precise operations. This enables us to offer a wide portfolio of ingenious polyurethane panel solutions. Manufacturing takes place in a computerized plant that creates pre-painted galvanized steel sheets (PPGS), pre-painted galvalume steel sheets, and stainless steel sheet fascias.

The sandwiched polyurethane foam (PUF) between the fascias has a density of 40 + 2 Kg/M3, ensuring high-quality insulation and structural integrity.

APPLICATIONS FROM INNOVATIVE PANEL SOLUTIONS

EPS panels have a wide scope of utilization and find applications in:

- Roofing

- Wall Cladding

- Partitions

- Walk-On Ceilings

- Prefabricated Shelters

- Accommodation Shelters

- Information Kiosks

- Health Centers

- Community Shelters

- Communication Shelters

Benefits from Frost Prefab Engineering

The shelf life, efficiency, and cleanliness of any building depend on the quality of the panels used in its construction. The prefabricated EPS panels manufactured by Frost Prefab Engineering offer the following features:

- International Standard Compliance: The pre-engineered EPS sandwich panels meet international building code specifications.

- Superior Energy Savings: Due to low thermal conductivity, these panels provide excellent energy efficiency.

- Flexible Design Options: Multiple options for fascia finishing and colors allow for customized aesthetics.

- All-Weather Proof Construction: Designed to withstand various weather conditions with low maintenance.

These insulated panels provide long-lasting value with controlled quality, accuracy, and speed of construction, enhancing functionality and application. Choose Frost Prefab Engineering for reliable, high-quality PUF panel solutions.